The

end float was checked on the rear bearing and set to .0003 inch by grinding the

surface of both thrust flanges with coarse paste on some glass. The end

float is measured with a feeler gauge between the shell thrust face and the

crank flywheel flange. If it is not 3 thou the shaft might seize when hot as the

aluminium bearing housing expands. After a trial fit with torqued up

bolts and some turning of the shaft some high spots were noted and ground down

again. Turn the shaft by fitting the starter dog. Note do not exceed 80lbs feet

torque as the dog may break. After 3 attempts I was happy. Note all traces of

paste were washed off as the soft white metal tends to absorb them. There are

many bearings that have oversize thrusts (10thou) so check end float. Obviously

oversize bearings will not fit in a standard shaft but they can be ground down.

An oversize shaft will have a bit too much end float with standard bearings.

The

end float was checked on the rear bearing and set to .0003 inch by grinding the

surface of both thrust flanges with coarse paste on some glass. The end

float is measured with a feeler gauge between the shell thrust face and the

crank flywheel flange. If it is not 3 thou the shaft might seize when hot as the

aluminium bearing housing expands. After a trial fit with torqued up

bolts and some turning of the shaft some high spots were noted and ground down

again. Turn the shaft by fitting the starter dog. Note do not exceed 80lbs feet

torque as the dog may break. After 3 attempts I was happy. Note all traces of

paste were washed off as the soft white metal tends to absorb them. There are

many bearings that have oversize thrusts (10thou) so check end float. Obviously

oversize bearings will not fit in a standard shaft but they can be ground down.

An oversize shaft will have a bit too much end float with standard bearings.

In

the absence of 30 thou oversize main shells I cut the flanges off some rears to

make these.

In

the absence of 30 thou oversize main shells I cut the flanges off some rears to

make these.

I check the shaft turns when the bolts are torqued up, slowly tighten them in

turn evenly to see which bearing is binding, as usually it binds with a reground

shaft and new bearings. Then turn the shaft about 10 revolutions and remove it

for examination. you can usually see a shiny bit where the bearing is grabbing.

Often the interference is on the width of the bearing caused by the filet radius

to the web. A smooth file will rectify the situation. when everything is turning

nicely clean all the oil off. Note the oil seal wear ring on this shaft that

needs to be avoided by offsetting the new seal.

I check the shaft turns when the bolts are torqued up, slowly tighten them in

turn evenly to see which bearing is binding, as usually it binds with a reground

shaft and new bearings. Then turn the shaft about 10 revolutions and remove it

for examination. you can usually see a shiny bit where the bearing is grabbing.

Often the interference is on the width of the bearing caused by the filet radius

to the web. A smooth file will rectify the situation. when everything is turning

nicely clean all the oil off. Note the oil seal wear ring on this shaft that

needs to be avoided by offsetting the new seal.

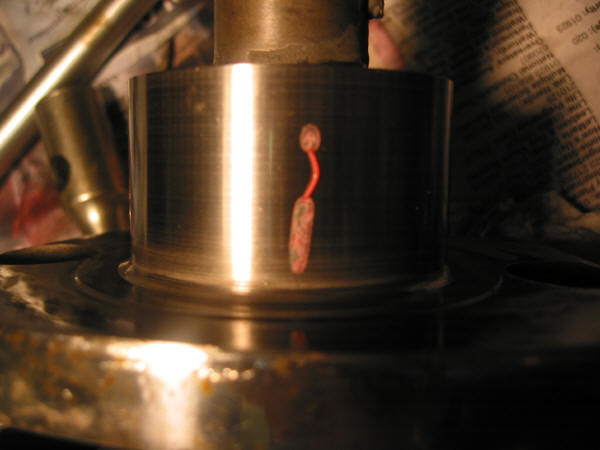

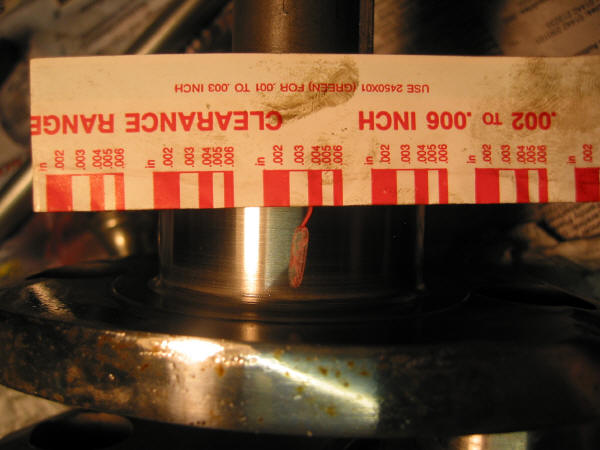

This shows the use of Plastigauge to measure the main bearing clearance. The

clearance is about .00035 Inch. the wire of plastic is squeezed flat when you

torque up the crankcase bolts. The width of resultant smear is then measured.

Note the shaft and bearing must be free of oil and must not be turned.

This shows the use of Plastigauge to measure the main bearing clearance. The

clearance is about .00035 Inch. the wire of plastic is squeezed flat when you

torque up the crankcase bolts. The width of resultant smear is then measured.

Note the shaft and bearing must be free of oil and must not be turned.